10 Mycelium

Material Explorations

Mycelium: The Leather Alternative

Nature is the ultimate designer, meticulously evolving organisms across billions of years in perfect harmony between functionality and aesthetics. We’ve taken inspiration from nature to develop sustainable commercial processes to design and manufacture the materials of the future.

Since 2015 ILE have been exploring the use of mycelium as an alternative to leather, working with leaders in the field to bring this novel material to the hands of the consumers.

Innovative Materials

Our aim is to provide engineered materials with homogenous physical and aesthetic characteristics, that mimic the natural properties of leather. Working with a library of mycelium strains and growing techniques, we are developing intuitive processes to grow mycelium sheets and further develop them into highly functional materials that celebrate the heritage of leather.

Our aim is to be completely sustainable through our raw materials, processes, and how we engineer the mycelium materials for use and end of life; as a means to take the fashion industry into an environmentally conscious future.

MATERIAL

What is Mycelium?

When most of us think of fungus, we imagine mushrooms sprouting out of the ground. Those mushrooms are in fact the “fruit” of the fungus, while the majority of the fungal organism lives in the soil interwoven with tree roots as a vast network of mycelium. Just like the vines or the branches on which fruit grows, mycelium is the name we give to the vast interconnected network of fibres that make up the body of the organism.

Nature’s best sustainable process

Mycelium’s role in decomposing organic matter is an important feature of our future material production. It has the ability to grow off food, agricultural, and other organic waste streams, capturing that carbon into our leather alternatives, giving them a new life.

Not only is this great for making new materials, but ILE is working towards developing a fully circular ecosystem, where the mycelium materials can be fed back into the biofabrication process and are biodegradable after their intended life cycle, unlike plastic based leather alternatives.

FROM CONCEPT TO PRODUCT

Why is it a possible alternative to leather?

Leather is made up of natural 3-dimensional fibrous weave of collagen fibrils. Leathers differ in total thickness, fibre bundle size and weave pattern, but offer a variety of raw material from which the tanner can select the skin type best suited for a particular end use.

Mycelium is the perfect candidate for biomimicry of leather, as it consists of networks of varying intertwined long fibers called hyphae. We engineer these by controlling their growth to develop a 3-dimensional structure that can be manipulated for thickness, density, and feel.

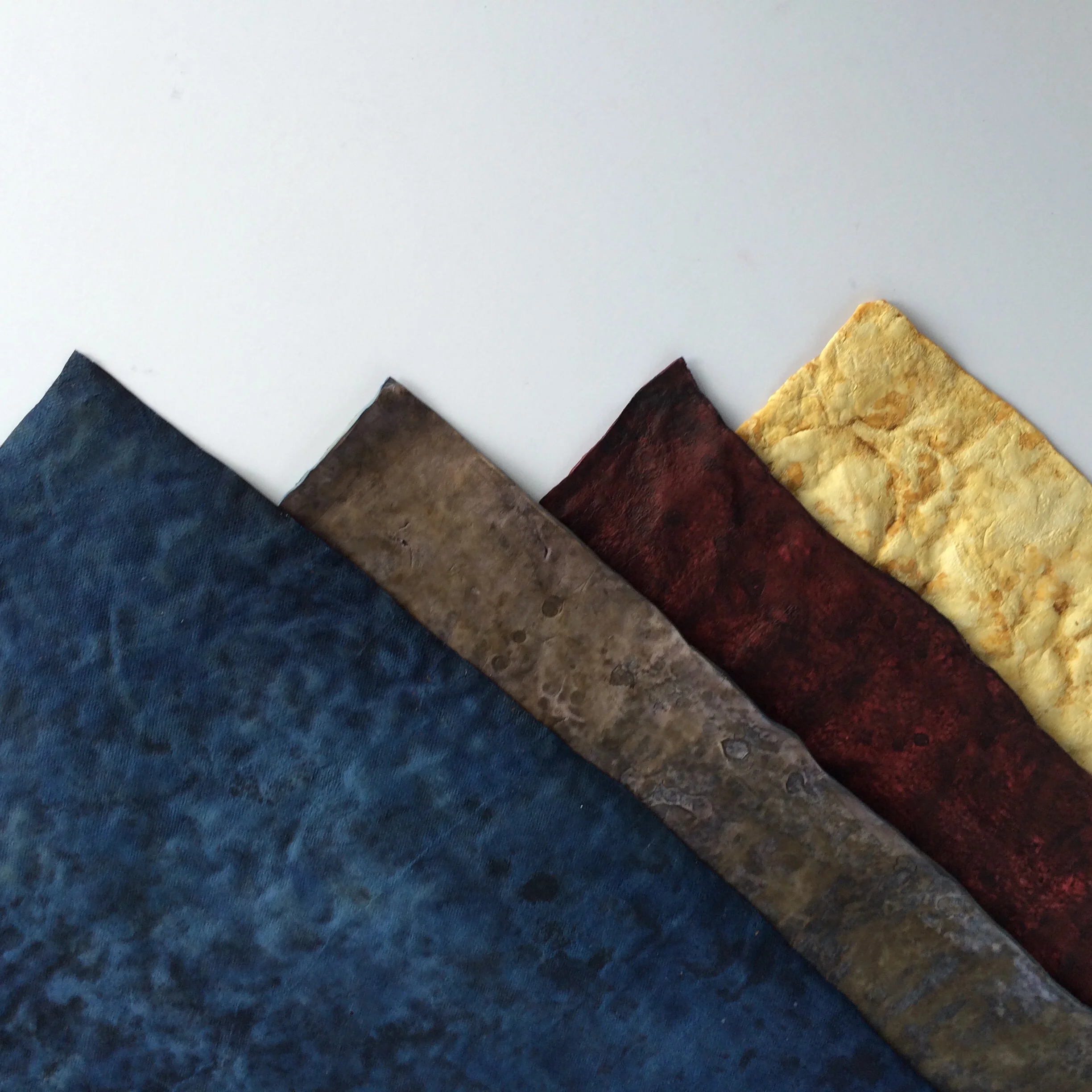

The Process of Colouring the Mycoteria

Building off our advanced material platform, ILE envisions a world where materials can be made on demand, in exact quantities, engineered to the specific requirements for the end user. With this we ensure materials of the future are sustainable. By implementing biomimicry to emulate the leather

structure, we celebrate the heritage of leather without the traditional supply chains. The main benefit of this technique vs other leather alternatives is that this is true bioengineering and biomimicry, allows us to control the final parameters based through environmental parameters and stresses, to grow the final material with our desired

properties and dimensions. Using leather as our inspiration, we are working towards mycelium materials that mimic the physical and visual features of leather, without the need for livestock to provide the raw material.

THE RESULT

The mycelium material is developed to have homogenous physical and aesthetic characteristics; strong enough that it can withstand regular use, while be soft and supple with a beautiful drape for perfect wearability.

A uniform surface provides the perfect canvas for our tanneries to transform the raw mycelium materials with textures and finishes. From a soft-touch velvety surfaces to smooth aniline leathers, our aim is to provide a full range of bioengineered leather alternatives.